- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Тренутна ситуација и изазови индустрије алатних стројева моје земље

2020-06-24

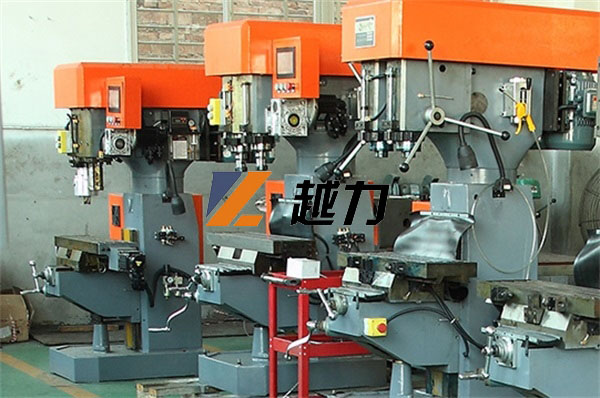

Quanzhou YueLi Automation Equipment Co., Ltd. located at the China plumbing town of Fujian Nan'an, it is a collection research and development, production, sales and service as a whole to dual spindle compound machine, drilling, tapping, milling, boring and special purpose machine, numerical control machine, vertical drilling, tapping, milling, boring machining center as the leading private enterprise. The company is committed to serve the plumbing, sanitary ware, automobile and motorcycle accessories, door closers, automobile engine cylinder block, cylinder head, aerospace, machinery manufacturing and other industries.

The machine tool industry is a strategic industry that is related to the national economy.It is a processing mother machine of the equipment manufacturing industry and a key equipment for processing and manufacturing.Almost all metal cutting and forming processes need to be realized with the help of machine tools.Domestic machine tools have been making progress and have been struggling forward.Compared with ten years ago and 20 years ago,domestic machine tools have made too much progress.State-owned machine tools only remember to take state subsidies.Private machine tool companies have given us hope.

Due to the late start of my country's industry,there is a certain technological gap with developed countries,the same is true of the machine tool industry.Fortunately,no matter it is a country or a machine tool company,it has never given up challenging the cutting-edge technology.After the"Made in China 2025"was proposed,the machine tool industry also set the goal of"high precision".

With the strong support of national policies,China's machine tool industry has developed rapidly and has been the world's first consumer and importer of machine tools for many years.The demand for machine tools has been increasing,and the total output value of the machine tool industry has also continued to increase.In terms of policies,the Chinese government has listed the development of large-scale,precision,high-speed CNC equipment and functional components in the metal cutting machine tool industry as one of the important revitalization goals of the country,which will also promote the rapid development of the industry.

development trend

Industrial automation is the basis for the realization of"Industry 4.0",and the most representative indicator of industrial automation is the popularity of robots.China currently has only 21 units per 10,000 people,which is very different from developed countries such as Japan and South Korea,and There is also a big gap compared with the average 55 units per 10,000 people in the world.Therefore,accelerating the development of industrial automation is the top priority of China's processing and manufacturing industry.

From 015 to 2018,my country's CNC machine tool industry gradually increased.In 2018,my country's CNC machine tool market reached 338.9 billion yuan,an increase of 10.73%over 2017.In 2014-2017,my country's CNC machine tool industry's finished products gradually increased.In 2018,my country's CNC machine tool products reached 25.4 billion yuan,an increase of 6.00%over 2017.

According to the statistics of the Bureau of Statistics,the profit of the machine tool industry has grown rapidly this year.The reason may be related to the low base in previous years.Among them,metal cutting machine tools,cutting tools,bamboo and wood machinery and other special equipment,and forming machine tools saw a relatively high increase.The main profit margin is higher in cutting tools,bamboo machinery and other special equipment,and functional components.Although the profit growth of the gold-cutting machine tool industry seems to be not low,the profit margin is only 4.92%,which is among the major sub-industries.The lowest,it can be seen that the metal cutting machine tool industry,which is dominated by general-purpose machine tools,is indeed very difficult.

Challenge

Quanzhou YueLi Automation Equipment co., ltd. was founded in 2013, with strong scientific research and production capacity, since the establishment of the company, committed to the development of stable performance, high efficiency automation equipment, adhering to provide customers with exquisite products and quality after-sales service, to create first-class automation equipment.

The machine tool industry is an industry with a large import and export deficit in the machinery industry.The deficit in 2017 was US$3.47 billion,of which the deficit of gold-cut machine tools was as high as US$5.5 billion.Among the gold-cut machine tools,the deficit of CNC machine tools reached US$2.16 billion and the deficit of machining centers It reached US$3.24 billion.It can be seen that the competitiveness of high-end machine tools is generally weak.

Enterprises in the machine tool industry are undergoing fierce differentiation.First,the situation of enterprises in the general-purpose metal cutting mainframe industry is poor,but the operation situation of special equipment enterprises is relatively good-supply-side structural reform must be accelerated.Second,although the state-owned key enterprises have deep technical accumulation,most of them are more difficult.

Quanzhou YueLi Automation Equipment co., ltd. was founded in 2013, with strong scientific research and production capacity, since the establishment of the company, committed to the development of stable performance, high efficiency automation equipment, adhering to provide customers with exquisite products and quality after-sales service, to create first-class automation equipment.

After the"Made in China 2025"was proposed,the machine tool industry also set the goal of"high precision".In the process of moving towards the goal,machine tool companies also need to solve the talent problem,innovation problem,transformation and upgrading problem,ecological problem,and the trade war provoked by the United States.The impact of the current trade friction between China and the United States is extensive but not First,the enterprise's confidence in exporting foreign trade,orders in the second half of the year,profits will inevitably be damaged;the transfer of Chinese orders and manufacturing to the outside world may be inevitable.

In the face of a trade war,we must calmly analyze,make good predictions,and anticipate,keep our heads clear,and turn pressure into motivation.It is necessary to aim at the core weak links of the industry,and strive to improve independent innovation capabilities,fill shortcomings,improve quality,improve own strength,and enhance core competitiveness to ensure industrial safety and enterprise development.

Despite many difficulties and severe challenges,the machine tool industry has made rapid progress in recent years.At present,it can basically meet the processing equipment required for power generation equipment and shipbuilding.The manufacturing equipment required for the aerospace industry has also made breakthrough progress.Among the four major processes in the automotive industry,domestic stamping lines and coating lines have advanced into the world Among them,the localization of welding,assembly lines and engine block and cylinder head processing lines is also making rapid progress.Therefore,we should never be arrogant and inferior,and we must be firm in our confidence to continue to promote autonomy.